Multiterminal DC networks. New challenges to overcome

Author: José Antonio Morales Sánchez | Position: R+D Project Manager | Published on: InfoPower

The present demand of power consumption requires new methods in order to be satisfied. Nowadays, conventional AC networks are to the limit to supply the whole population. Thus, the use of DC networks for energy transport can solve this global problem. The numerous advantages —better efficiency, better signal quality, larger distances for energy transport, possibility of using an undersea or subterranean cable to shorten distances and to reduce costs, easy integration of renewables, etc.— make their exploitation very promising. Nevertheless, there are still many challenges to overcome.

The technology used in the semiconductors manufacturing has evolved to offer better performances. The use of new materials for the production of these devices increases their operation. Thus, traditional manufacturing methods based on silicon (Si) are substituted by other materials as silicon carbide (SiC) or gallium nitride (GaN). This change allows handling greater powers with more elevated commutation frequencies and lower refrigeration needs. The implementation of new control techniques is central for an optimal exploitation of the capacity of the semiconductors.

VSC-HVDC (Voltage Source Converter – High Voltage Direct Current) systems use a DC link to transmit energy at high voltage. The already installed VSC-HVDC systems use a point to point connection technology, where one generation point supplies one consumption point. If the DC link fails, the supply is interrupted. It is necessary, then, to find a solution that increases the robustness of the systems in order to avoid a lack of the supply of a city. One solution could be the creation of a multiterminal network for generation and consumption, which can assume a failure in any link and guarantees a constant supply. However, it is highly complicated to disconnect the link that has caused the problem from the rest of the network without that the latter stops working. Right now, DC breakers solutions, capable of carrying out this disconnection with high current and voltage levels, are too expensive and the suppliers are very few.

GPTech, pioneer company in the development of power electronics devices that use the state of the art technology to provide new solutions to the renewable energies sector, has as one of its main objectives the development of more efficient, reliable and inexpensive solutions. GPTech is studying new topologies and control strategies to facilitate the creation of a robust and safe pan-European network, capable of covering the continental energy necessity, with multiple interconnected points of generation, distribution and energy consumption.

GPTech is developing a VSC-HVDC converter, based on a modular topology. This allows an easy scalability of the solution for high powers, avoiding thereby the problem in DC networks if a fault in a DC link occurs. The company aims, as well, to reduce the manufacturing and maintenance costs of this kind of converters while assuring their operation in extreme conditions.

The control system is an important investigation focus and GPTech contributes all its previous experience in the development of control systems for its devices. The problems in VSC-HVDC systems and the control necessities require a constant change of the control algorithm and its adaptation to present need placing emphasis on the control response to failures so the converter works consistently.

Analyzing in depth the problem of short-circuit currents caused by a failure in any part of the circuit, for conventional AC grids a big variety of devices exist and are offered on the market such as disconnectors, circuit-breakers, overcurrent circuit-breaker, air-break contactor, relays, etc. These devices offer several solutions to isolate, in an easy, cheap and fast manner, that part of the circuit that is causing the fault. This is possible due to the sinusoidal nature of the AC signal, which allows the zero crossing voltage. When the zero crossing voltage takes place, the devices previously mentioned carry out the disconnection of the failure part. In this point, there is no difference of power among terminals, so the risks of producing electric arc, potentially dangerous for the equipment, disappear.

Zero crossing voltage does not take place in DC grids. Thus, a disconnection without any danger for the equipment becomes a complicate issue. How this problem can be solved? DC disconnectors are expensive and only a few manufacturers offer a valuable solution in terms of prize and space. Therefore, searching a topology supported in an efficient control that eliminates the use disconnectors would mean a revolution.

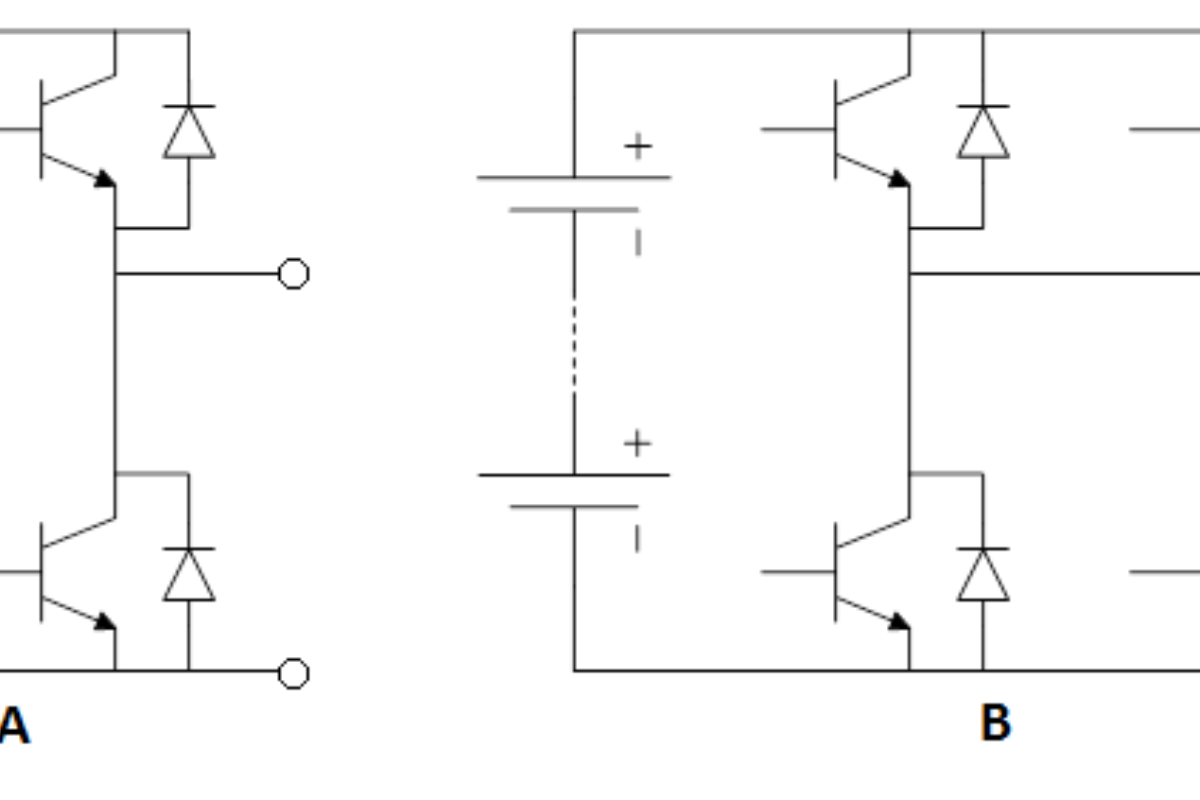

The existing multilevel topologies for VSC-HVDC converters introduce cells composed by half or full IGBTs bridges with an antiparallel connected diode. A solution based on half bridges use fewer superconductors and is, therefore, cheaper in terms of the cell. Nevertheless, it does not offer protection against short-circuits produced in the DC side. Although superconductors can interrupt the current, electricity will be able to circulate through the diodes. Then, it is necessary the use of DC disconnectors, which raises the cost of the equipment.

On the other hand, cells using full bridge are even more expensive, but eliminate the problem whatever the sense of the current is. A diode with reverse biased will avoid the free circulation of the current when semiconductors open. In the Figure 2, the different paths followed by the current in any case are shown. In the half bridge topology, the current circulates freely while in the full bridge topology, the diodes stop this flux. They allow the current circulation in capacitors, whatever their direction is, as well as their extinction in the equalization strengths that are found in parallel.

Nowadays, new topologies combining both options are studied. Hybrid topologies take advantages of both topologies while looking for an optimal compromise between the cost and the protection of the equipment.

GPTech contributes more than ten years-experience in the manufacture of converters to cover different necessities, as well as in the creation of new control algorithms to take the most out of converters. Its aim is the use of the advantages offered by the technological advances in the new devices used to carry out the commutation. The search of innovative solutions to be adapted to the new necessities is always a main objective for the company. The potential market that offers those HVDC systems makes interesting the development of a revolutionary and original solution that optimizes all the elements of the system.

The awareness in Europe of creating a continental supply network generating from natural resources with the aim to reduce the 20% of CO2 emissions in the coming years; the key role that Spain plays in this scenario, as a country with a large amount of natural resources to be utilised and, also, as a nexus of union with the north of Africa; and the suitability of using HVDC systems for the integration of this generated energy makes GPTech focus on the development of a competitive and innovative solutions that place the company in a privileged position with respect to the rest of the companies.